The development and construction of a Prefamac machine is preceded by an entire process. From checking feasibility and efficiency, international availability of parts to extensive testing in all working conditions. Always with particular attention to ergonomics, hygiene and safety of the machine operator. Only this way we can build state-of-the-art machines in ease of use and durability.

Our machines last a very long time: at many customers, including major industrial players who work 24 hours a day, our machines have been running for over 20 years with minimal maintenance. Prefamac not only offers value for money, you can also count on expert advice and excellent after-sales service. In addition, we can provide project planning & engineering if the machines are connected to existing equipment.

For the various operations, we have machines with different executions and belt widths up to 1600 mm. Customization is one of our strengths.

With the Prefamac JAMES machine, you can apply interiors to standard and mini chocolates, as well as to chocolate tablets. Manons and buttercream fillings can also be moulded with the James.

The tempering process guarantees chocolate with a satin shine and a bite. Our semi-industrial tempering machines stand out because of the constant maintenance of the correct temperature, and the many possibilities inherent in the use of PLC (or programmable logic control). Content of 15, 30 and 60 kg available.

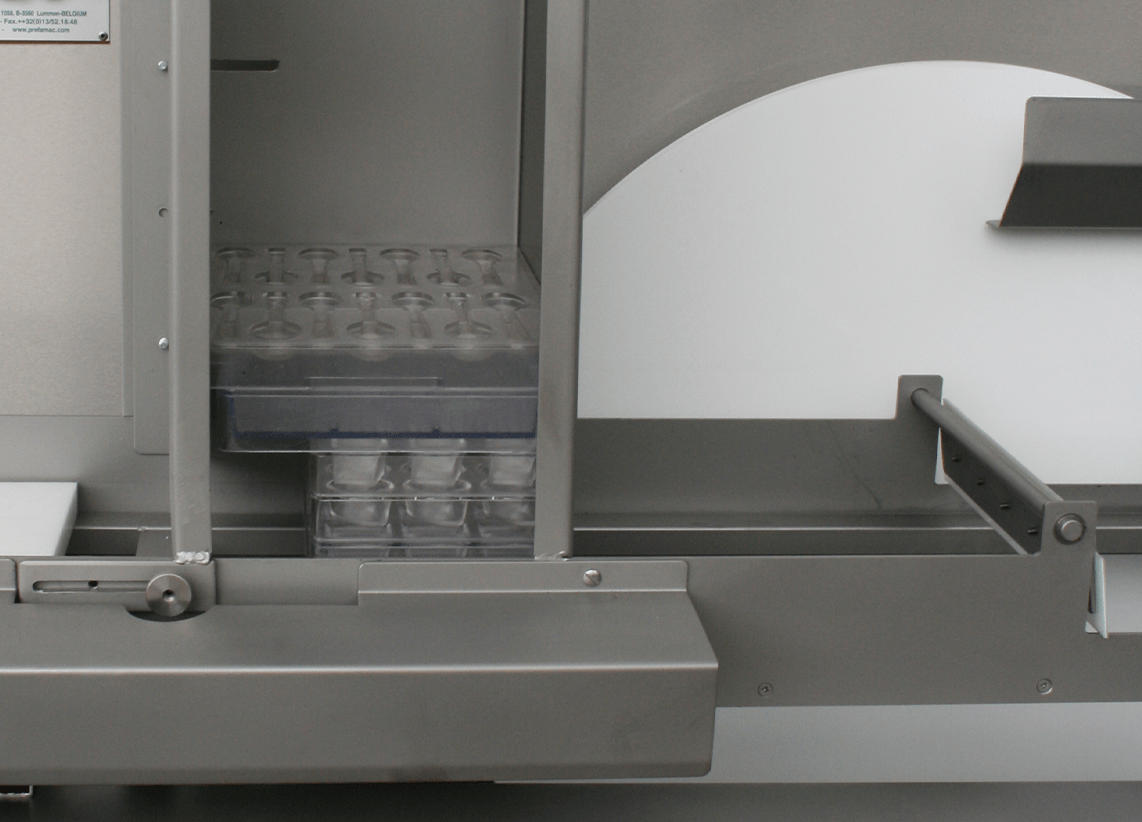

After melting the chocolate, it is manually tempered with a moulding machine. This task is only reserved for the specialized chocolatier with expertise. Moulding with moulds is used for pralines/bonbons or hollow figures. Content of 15, 30 and 80 available, but also multiples.

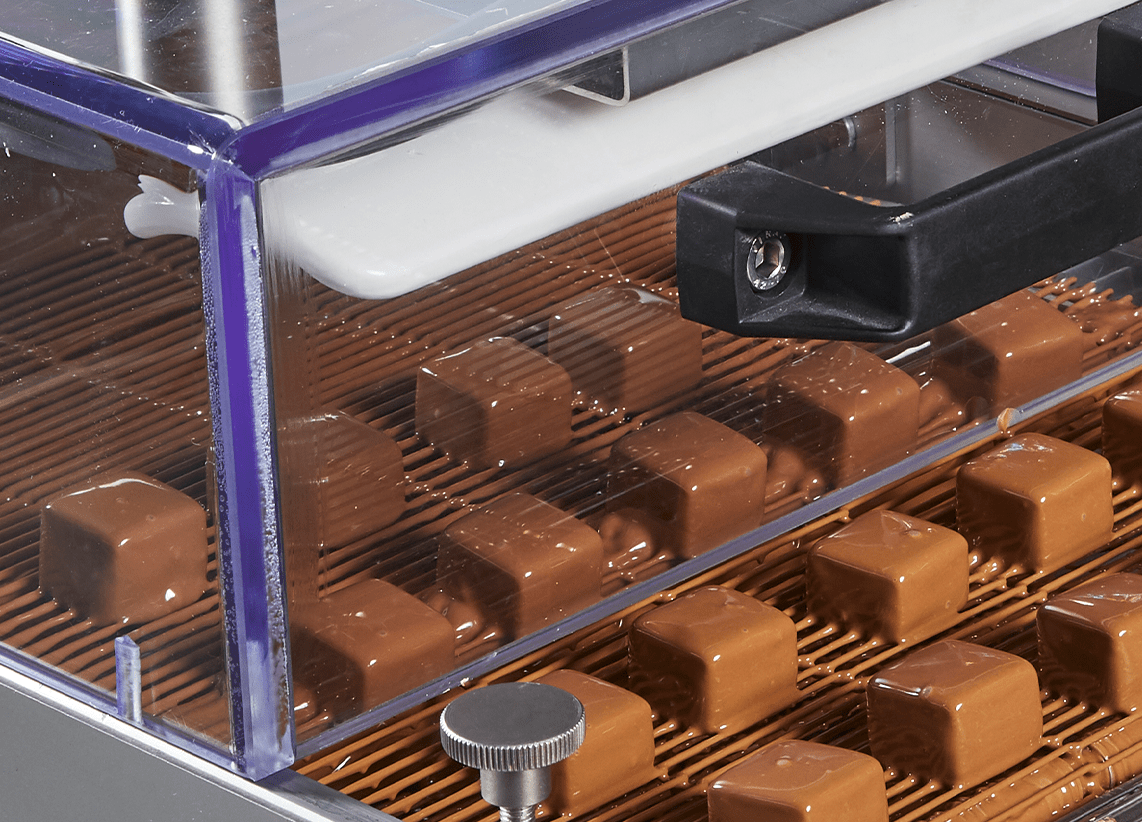

An enrobing belt is placed on a moulding machine or tempering machine to enrobe cookies, truffles or pralines with chocolate (just the bottom or the entire product). Various bandwidths are available.

With a flaking machine, one or several blocks of chocolate will be transformed into beautiful flakes. Lengths and thicknesses of flakes can vary. Various types of flaking machines to decorate truffles, pies, cakes, donuts, ….

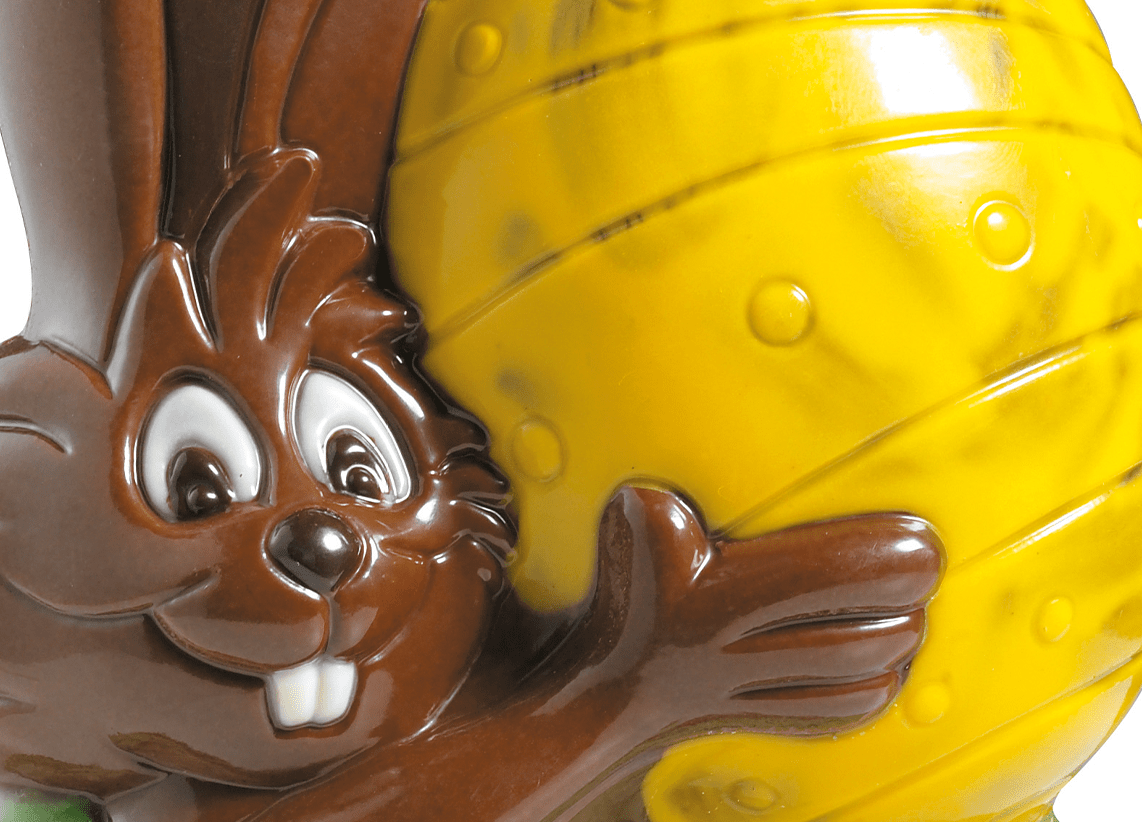

Hollow figures or hollow goods are produced with a spinning machine. There are several fun figures for every season, every holiday, ball game or sport that will surprise young and old.

A pneumatic scraper is placed on a moulding machine or tempering machine. A container of chocolate moulds is replenished, and one by one the moulds are filled with chocolate and then vibrated. Suitable for the production of tablets, napolitains, but also for closing moulds.

As the name suggests, this cabinet will heat. For example, an enrobing belt can be kept warm overnight, or moulds can be heated before use. It can also be used to melt chocolate (in separate trays). You can also prepare chocolate blocks in the heating cabinet so that they can be turned into beautiful flakes.

As the name suggests, our melting trays will heat and melt chocolate autonomously, i.e. with their own electrical connection. The inner trays are always interchangeable, so that these devices can be used in a handy and compact way. Various sizes are available.