Because traceability within the food chain is becoming increasingly important, but also because any waste of energy is out of the question, Prefamac Chocolate Machines has developed its Clooney1 tempermeter. Any form of over- or under-crystallised chocolate must be avoided in the tempering process, and measuring is knowing. Wasting energy by tempering again and again until a correct result is achieved must be avoided.

The big advantage of the Prefamac Clooney1 tempermeter is that the temper index is known within 5 minutes ! This is super-fast, and ensures that operators are also quicker to perform this necessary check.

Using the machine is also very easy :

The design of the Clooney1 with coffee cups (😊) is not only beautiful, but has a fully worked-out function for quality, ease of use and solidity :

But what exactly is this tempering process and determining the temper index ?

The main component of chocolate is cocoa butter. Cocoa butter has the property of being polymorphic, meaning it can occur in different crystal forms. These crystal forms are created when chocolate is (cooled). The crystal shape in which cocoa butter mainly crystallizes determines what properties the chocolate possesses.

Beta V type crystals in particular provide a pleasant hardness, a shiny solid texture and a typical hollow sound when breaking (or biting into) the chocolate. Tempering is the process of obtaining these stable Beta V crystals. A tempermeter measures the quality of the tempering or tempering process of chocolate, which has been tempered via a manual or automatic method. Tempering is therefore the most important measurement that should characterize chocolate, which is why Prefamac has developed a tempermeter.

A tempermeter functions through the physical properties of chocolate to determine a temper score or temper index. The chocolate sample is inserted into an isothermal cooling element. Chocolate gives off ‘latent heat’ during its cooling process when it passes from a liquid state to a solid state (crystallizes).

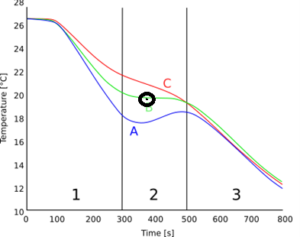

This transition or phase transition is visible on the tempermeter screen. When and how fast this crystallization process occurs depends on the degree of tempering of the chocolate. In this way, a distinction can also be made between under-, over- and correctly tempered chocolate to determine what the quality of the final product will be.

The turning point that occurs in the cooling curve is called the inflection point. An inflection point is that point on the curve where the bending changes from convex to concave or vice versa. The second derivative of the curve in question thus changes sign at this point. With ideally tempered chocolate, a curve with a cooling rate of 0°C/min will arrive at the inflection point. So the measurement results or the screen or the print-out on paper also always show when and at what temperature the inflection point is located. These data are also saved, just to make different measurements comparable according to the inflection point.

Curve A shows under-tempered chocolate, curve C over-tempered chocolate.

Once this cooling process is complete, the TI or temper index appears, which is a digit. A digit with one decimal unit behind it. This digit should preferably be between 4 and 6. Please note, the common manual tempering machines ‘without PLC’ so with a circuit board or PSB are usually limited to a score 3, which is rather (too) low.

The full user manual for the Clooney1 when you buy it is of course much more detailed. This is also the case for the safety and maintenance instructions.