The years have literally flown by. Working daily with creative people in the production of chocolate and cookies is obviously very motivating. Thanks to you, our customers, we have gained a mass of inspiration to keep developing innovative machines. After all, we continue to innovate despite the recent crisis. We know that our customers today …

Because traceability within the food chain is becoming increasingly important, but also because any waste of energy is out of the question, Prefamac Chocolate Machines has developed its Clooney1 tempermeter. Any form of over- or under-crystallised chocolate must be avoided in the tempering process, and measuring is knowing. Wasting energy by tempering again and again …

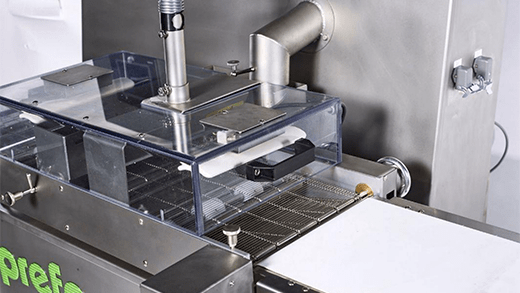

Because the quality of our Prefamac enrobing machines is really top notch, in this blog we wish to take a closer look at the specific features of this machine. And this more specifically for the SWITCH ULTRA type. An enrober with an interchangeable chocolate tray and also with an interchangeable chocolate bath (for the feet). …

At Prefamac Chocolate Machines we can tell you everything about melting and mixing kettles. Our team prefers to produce completely customer-specific kettles as shown in the photo below. All-in with stainless steel platform, rotary lobe pump or gear pump, double-walled piping and additional heating. Special level detections depending on the application or ‘consumer’ of the …

When we speak of cocoa nibs, these are small pieces of fermented, and carefully selected cocoa beans, which remain after roasting and peeling. We also speak of Raw Cacao, because these nibs can also be eaten without question. In Michelin-starred restaurants, the nibs are also regularly used as a garnish. The new PrefaNIBS machine from …

A few years before corporate social responsibility (CSR) became an active working point for many companies all over the world, Prefamac Chocolate Machines was already working on this quite intensively.

The European Union wants to be climate neutral by 2050. In just nine years, our CO2 emissions must also be reduced by at least 55%. These are ambitious plans.

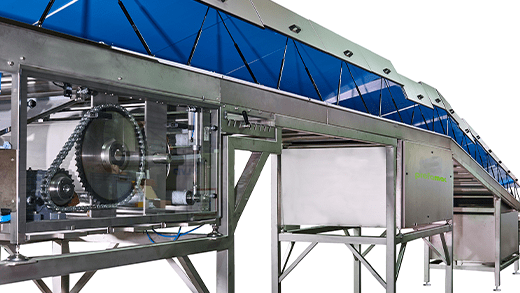

Whether you need to cool donuts, biscuits, truffles, pralines or waffles, Prefamac has the right cooling tunnel available for every product and every quantity.

The focus of chocolate makers and cookie manufacturers is of course deliver a final product of the highest achievable quality.

The focus of chocolate makers and cookie manufacturers is of course deliver a final product of the highest achievable quality.

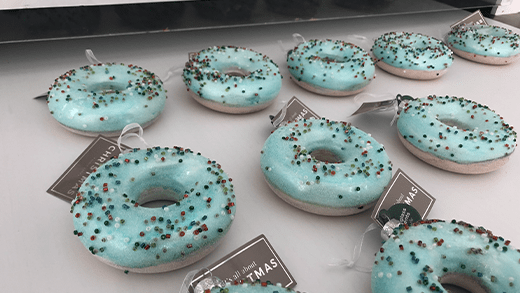

At Prefamac we constantly think of parties. Saint Nicholas, end-of-year parties, spring parties, .. we are always ready for it!

You either have too little space, you want to work very quickly or you have a product with special sizes.